Procedure

1 SURFACE PREPARATION

The surface shall be cleaned thoroughly of all contaminants like dust, traces of curing compound, oil and grease. All surface imperfections and protrusions shall be removed and repaired. Structurally unsound and friable concrete must be removed and repaired with a suitable repair mortar.

2 PRIMING

Solvent based bituminous primer shall be applied to a clean and dry surface. The viscosity of the primer is low, so it easily penetrates into the concrete pores which promote the adhesion between the membrane and the concrete surface. In addition to that the primer also acts as a binder for the dust which gets accumulated on the concrete surface even after cleaning.

3 ALIGNMENT

The membrane sheet are aligned from the lower slope point or drainage side towards top level of the slope from all sides so the flow of water is over or parallel to the plies, but never against the lap. Parapet walls and balcony terrace are also included for complete isolation.

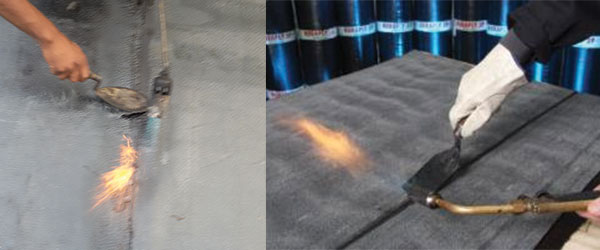

4 TORCHING

APP membranes are installed by Torch method using commercial LPG Gas cylinder and gas torch.

5 CARPET FINISH

After installation of membrane the sides and overlaps are sealed with trowel to attain a carpet finish single layer look

6 FINAL FINISH SILVER PAINT

Silver paint is coated over the treatment to prevent the treatment from absorbing heat, preventing penetration of UV rays and to minimize cooling load.